FDA’s Food Traceability Rule

Does your restaurant need to follow the FDA’s Food Traceability Rule?

The Food & Drug Administration’s (FDA) Food Traceability Rule (also called ‘FSMA 204’) is intended to quickly identify, and remove from distribution, potentially contaminated foods. The rule is expected to result in fewer foodborne illnesses and deaths. Beginning in 2026, restaurants that include foods from the ‘traceability list’ – foods that are more frequently implicated in foodborne disease outbreaks – will need to meet specific record keeping requirements. While 2026 is still in the far future, it is in a restaurant’s best interest to begin preparations now.

The Association will:

- Update this site with the latest information about the FDA’s Food Traceability Rule

- Provide guidance and tools to help the industry follow the new rule

Association Tools and Resources

These resources have been prepared by the Association to help the restaurant industry with FDA Food Traceability Rule preparation.

Restaurant Traceability Evaluation

This tool will help you determine if your restaurant must follow the FDA's new Food Traceability Rule. Click on the answer choice of "yes" or "no" for each question to see what your restaurant may need to do.

We recommend opening on a desktop. (Download size is 28 MB)

Restaurant Food Traceability Rule Guidance

The National Restaurant Association has created this Restaurant Food Traceability Rule guidance document to help restaurants prepare to follow the FDA’s Food Traceability Rule before the January 2026 deadline.

FDA Resources

The FDA’s Food Traceability Rule and communications to industry about the new rule are available at the links below.

- Food Traceability List- FDA version

- FDA's June 26, 2023- Constituent Update

- FDA’s Traceability FAQs

- FDA's Traceability Rule: Federal Register Notice

- FDA's Full and Partial Exemptions to the Food Traceability Rule

- FDA’s traceability website

- FDA's Risk-Ranking Model for Food Tracing

- Retail Food Establishments (RFEs) and Restaurants: What Records Do I Need to Keep for the Food Traceability Rule?Español (Spanish) | 中文 (Chinese, Simplified) | Tiếng Việt (Vietnamese)

- Retail Food Establishments (RFEs) and Restaurants: What You Need to Know About the Food Traceability Rule

Español (Spanish) | 中文 (Chinese, Simplified) | Tiếng Việt (Vietnamese) - Retail Food Establishments (RFEs) and Restaurants: What You Need to Know About Establishing and Maintaining a Traceability Plan for the Food Traceability Rule

Español (Spanish) | 中文 (Chinese, Simplified) | Tiếng Việt (Vietnamese)

Additional Resources

The following links provide resources that may be useful to your restaurant as you prepare to follow the Food Traceability Rule.

Disclaimer: These resources are not endorsed by the Association. They are being shared as options for helping restaurants comply with aspects of the Food Traceability Rule.

- Time/Date Calculator Online Tool The new Rule requires restaurants to maintain records for 180 calendar days. This free online Time/Date Calculator can help calculate 180 days so you can record when it is safe to destroy records.

- Unique ID Generator. The new Rule requires that reference documents include unique ID numbers. If a reference document does not have a unique ID number you can use this free online tool to generate universally unique IDs or globally unique identifiers.

FDA Food Traceability Rule FAQs for Restaurants

The answers to these Frequently Asked Questions (FAQs) are based on our understanding of the FDA’s Food Traceability Rule at this time. These answers will be updated should new information become available that provides greater clarity.

Definition FAQs

The FDA used new words and phrases in their Food Traceability Rule that restaurants may not be familiar with. These unfamiliar words and phrases appear in bold in the FAQ and definitions are included so you can become familiar with their meaning.

-

What is the Food Traceability Rule (Rule)?

These are the regulations that the FDA created to go with the Food Safety Modernization Act (FSMA). The full Rule and associated guidance can be found here. -

When will the FDA begin enforcing the Rule and begin inspections?

The FDA says that it will not begin routine traceability inspections until sometime in 2027. The FDA may conduct traceability inspections any time after January 20, 2026, and before 2027 if it has reason to do so, for instance, during a foodborne illness outbreak investigation.

Before enforcement and routine inspections in 2027, the FDA may provide fact sheets and opportunities for businesses to ask questions about the Rule during other routine FDA inspections. -

What is a Product Tracing System (PTS)?

The Product Tracing System (PTS) is an internal technology system that is being created for the FDA to use to track all food in the United States or offered for import into the United States. The new PTS system will receive and analyze industry food traceability data. -

What is the FDA’s Product Tracing System (PTS), and what will it do?

The Product Tracing System (PTS) is an internal technology system that is being created for the FDA to use to track all food in the United States or offered for import into the United States. The new PTS system will receive and analyze industry food traceability data.

Once food traceability data is uploaded, the PTS will automatically process the information into a visibility data standard called EPCIS (Electronic Product Code Information Services). Note: It is not a requirement for the industry to send food traceability data to the FDA in EPCIS format.

The PTS will have strict data security and network security protocols. Only government users with permission will be able to access the data. FDA will protect all confidential information from disclosure. -

How can I provide food traceability data to the FDA?

When the FDA requests that the industry provide tracking data on an FTL food, there will be a couple of ways to provide the information:

- Email it to the FDA, and the FDA will then upload the data into their new Product Tracing System (PTS).

- Industry can directly upload an electronic sortable spreadsheet or other traceability records into the FDA’s Safety Reporting Portal (SRP). Note: This portal is now being updated to add a traceability-specific landing page. The Association will add the link to this page once it is available.

The FDA will provide more information on how the industry can upload or provide traceability documents before the January 20, 2026, deadline. -

What is an Advanced Shipping Notice (ASN)?

An ASN is a notice sent by the shipper ahead of a shipment informing that delivery is about to arrive. ASNs are used in Electronic Data Interchanges (EDIs). The ASN can contain order information, product descriptions, packaging types, and carrier information. -

What is a Critical Tracking Event (CTE)?

A Critical Tracking Event (CTE) is the time something significant happens with a Food Traceability List (FTL) food. These “events” in the life of an FTL food include:- Growing or raising

- Creation

- Harvesting

- Cooling before initial packaging. This includes produce that has been harvested and then cooled. It does not include cooling at a restaurant.

- Initial packing of a raw agricultural commodity (RAC). An RAC is any food in its raw or natural state, including all fruit that is washed, colored, or otherwise treated in unpeeled natural form before marketing. This does not include an FTL food initially received from a fishing vessel.

- Receiving

- Transforming the food

- Shipping

-

What is an Electronic Data Interchange (EDI)?

An EDI is an electronic data exchange of business information between two or more organizations electronically. This typically replaces using paper documents (ex., purchase orders or invoices). -

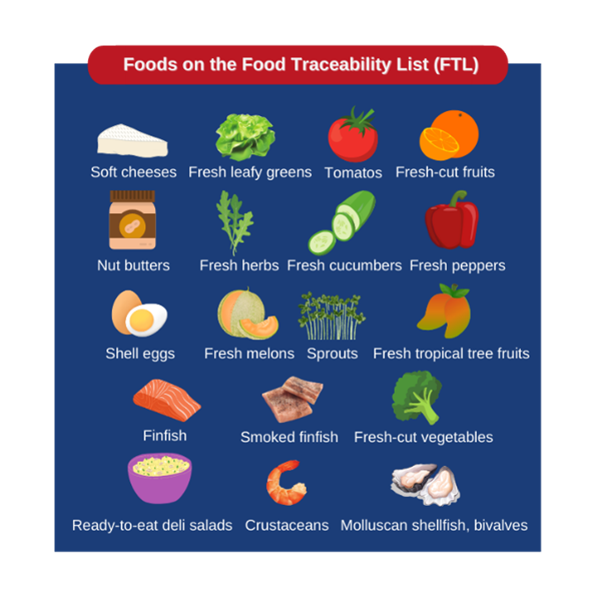

What is the Food Traceability List (FTL) or Food Traceability List Food (FTL Food)?

These are the foods that the FDA put on a list because research indicates they are at a higher level of risk for causing foodborne illness.

This is the Food Traceability List (FTL): soft cheeses, fresh leafy greens, tomatoes, fresh-cut fruits, nut butters, fresh herbs, fresh cucumbers, fresh peppers, shell eggs, fresh melons, sprouts, fresh tropical tree fruits, finfish and smoked finfish, fresh-cut vegetables, ready-to-eat deli salads, crustaceans and molluscan shellfish, bivalves.

If you have questions or need more clarity about what is on this list, please review the Food Traceability List- FDA version. -

What is a Food Traceability Plan (FTP)?

A Food Traceability Plan explains how your restaurant creates and maintains FTL Food required information. It is intended to help the FDA quickly review and understand the information you provide during a foodborne illness outbreak investigation related to food(s) on the Food Traceability List. -

What is Food Transformation or Transformation?

Transformation occurs when a Food Traceability List (FTL) food is mixed or blended with other foods, repacked/repackaged, and then shipped to another location, or is relabeled.

Transformation does not include:- The initial packing of an FTL food when it is first assigned a Traceability Lot Code (TLC).

- Any activities that happen before the FTL food is packed and assigned a TLC (ex. Harvesting or Cooling - not cooling at a restaurant)

- When you break large cases of an FTL food into smaller units, as long as it is not repackaged into smaller units or ship them.

- Taking a pallet that includes many individual packed cases and breaking the individual cases into separate shipments - as long as none of the individual cases are re-packaged, relabeled or mixed/blended in the process. If they are, then food transformation has occurred.

-

What is a Key Data Element (KDE)?

A Key Data Element (KDE) is information related to a FTL Food’s Critical Tracking Events(CTEs). KDEs include: the Traceability Lot Code, quantity & unit measure of the food, food description, previous food suppliers’ location, restaurant receiving location, date received, and reference documents with identification numbers.

All KDE information must be kept for a minimum of 2 years.

Some KDEs must be provided to other food supply chain businesses and maintained on-site. In some situations, a restaurant might receive a FTL food record with KDEs from a supply chain partner (e.g., the shipper) and would not need to create their own new record. -

What is a Kill Step?

A kill step means doing something that kills or damages organisms that cause disease in a food.

Example of a kill step: Cooking chicken to an internal temperature of 165 degrees.

Example of what is not a kill step: Washing some fruit. A washing process reduces the number of organisms that cause disease but does not kill them. -

What is a Raw Agricultural Commodity (RAC)?

A raw agricultural commodity (RAC) is any food in its raw or natural state, including all fruit that is washed, colored, or otherwise treated in unpeeled natural form before marketing. This does not include an FTL food initially received from a fishing vessel. -

What is a Reference document and reference document number?

Reference documents are bills of lading, purchase orders, advance shipping notices (ASNs), work orders, invoices, database records, batch logs, production logs, field tags, catch certificates, and receipts. The reference document number is the number assigned to the reference document. -

What is a Traceability Lot Code (TLC)?

A traceability lot code is an alphanumeric code/barcode used to uniquely identify a specific batch (lot) of food from the business that was originally created, transformed, first received from a fishing vessel, or packaged the FTL food and assigned a code to the batch. Lot-based recordkeeping is not required when an FTL food is harvested or at any point before the initial packing or first land-based receiving.

Restaurants only need to assign a TLC if they are shipping food to another location.

A lot code, batch code, or other production code for an FTL food can be used as a traceability lot code if it meets the definition stated above.

There are no limits on how much of an FTL food can be put into a lot or how many different sources (including different fishing vessels) the food can be from.

Many businesses are still working on solutions for capturing and transmitting traceability lot code information. -

What foods are on the Food Traceability List (FTL)?

Food Traceability List- Soft cheeses

- Fresh leafy greens

- Tomatoes

- Fresh-cut fruits

- Nut butters

- Fresh herbs

- Fresh cucumbers

- Fresh peppers

- Shell eggs

- Fresh melons

- Sprouts

- Fresh tropical tree fruits

- Finfish and smoked finfish

- Fresh-cut vegetables

- Ready-to-eat deli salads

- Crustaceans

- Molluscan shellfish, bivalves

If you have questions or need more clarity about what is on this list, please review the Food Traceability List- FDA version. -

Why are these foods on the Food Traceability List?

These are the foods that the FDA put on a list because their research indicates they are at a higher level of risk for causing foodborne illness. -

Do small restaurants need to follow the FDA’s Food Traceability Rule?

Restaurants selling less than $250,000 of food yearly may not need to follow the FDA’s Food Traceability Rule.

Please download the Restaurant Traceability Evaluation (located in the upper right corner of this page) to determine if your restaurant is required to follow the rule as there are some exemptions. It is your responsibility to identify if any exemptions apply to your restaurant. -

To calculate average annual food sales for the small restaurant exemption- is the total based on how much Food Traceability List food (FTL Food) is sold each year, or is it all food sold in a year?

This exemption must be calculated on all the food the restaurant sells yearly, not just the FTL foods. -

Franchise owner with multiple restaurants, does the < 250K annual food sales exemption apply to the total annual average food sales for all the restaurants combined or for each individual restaurant?

The rule applies to each individual restaurant’s annual average food sales, not all the restaurants owned totaled together. It is possible that some restaurants of a franchise owner will need to follow the FDA’s Food Traceability Rule, and others will not. -

Is it the individual franchisee owner or the corporate owner for a restaurant chain that is responsible for following the FDAs Traceability Rule?

Unless the restaurant is exempt from the FDA’s Food Traceability Rule (download the Restaurant Traceability Evaluation (located in the upper right corner of this page) to determine if your restaurant is exempt), each individual restaurant location is responsible for following the requirements of the FDAs Food Traceability Rule. It is ok for a restaurant location to have their corporate headquarters establish and maintain the required records on their behalf. However, the restaurant location is still responsible for ensuring that the records can be provided to the FDA within 24 hours of a request for review. -

Does the rule apply to commissaries or central kitchens that produce and ship product to stores or other restaurants? If so, what Key Data Elements (KDEs) would they have to maintain?

Yes, the rule applies to commissaries and central kitchens that prepare food and then ship the food to a restaurant or store. KDEs must be maintained for any FTL foods received, shipped, or transformed (blended, mixed, repackaged or relabeled). -

Are restaurants that use a central kitchen model required to keep records for foods on the Food Traceability List that are ingredients in menu items that are sent to other restaurant locations?

Yes, restaurants that use a central kitchen model transform (mix, blend, repackage, relabel) and ship menu items before they are sold to consumers. The FDA views this model as operating as a manufacturer/processor/distributor. As a result, the central kitchen must keep the Key Data Element records for two years. -

Does my restaurant need to follow the FDA Traceability Rule if we get all our food from a farm?

Restaurants that get all their food directly from a farm may not need to follow the FDA’s Food Traceability Rule. However, restaurants that get all their food directly from a farm do need to:- Document the name and address of the farm(s) you purchase from.

- Document type(s) of food you purchased from the farm(s).

- Maintain the records for 180 calendar days. Time/Date Calculator Online Tool can help.

Sample spreadsheet

Name of Farm Farm Address Type of Food Received

from Farm(s)Date Received Delete Date of Record Johnson Farm 125 Farm Rd

Washington, DC 20001Spinach 6/28/2023 12/25/2023 -

Are restaurants required to keep records for Food Traceability List (FTL) foods that are transformed and sold directly to consumers?

Restaurants do not need to keep records on the FTL foods they transform (in other words: mix, blend, repackage, or relabel) UNLESS the restaurant acts as a central kitchen/commissary or manufacturer/processor. If the restaurant or central kitchen/commissary is shipping/sending FTL foods or transformed foods that include FTL foods, then they will need to keep records. The FDA considers this to be a manufacturing/distributor activity. -

Does the kill step exemption apply to foods made in restaurants that are given to consumers?

No, the kill step exemption does not apply to restaurants that give food directly to consumers. However, the restaurant must keep records of all FTL foods they receive. -

What is the deadline for restaurants to begin following the FDA’s Traceability Rule?

The compliance deadline is January 20, 2026. It is important for restaurant operators to understand how the rule may impact current business practices long before the January 2026 deadline, as most restaurants will need time to develop solutions to meet the new requirements and implement them.

Download and complete the Restaurant Traceability Evaluation (located in the upper right corner of this page) to determine if your restaurant may need to follow the FDA’s Food Traceability Rule. -

What information must be included on the restaurant’s Food Traceability Plan?

A food traceability plan explains how your restaurant creates and maintains required information related to FTL Foods. It is intended to help the FDA quickly review and understand the information you provide during a foodborne illness outbreak investigation related to food(s) on the Food Traceability List.

The Food Traceability Plan must:- Explain the process used to maintain the required food tracking records.

- Describe how you identify foods on the Food Traceability List that are on your menu at any time.

- Provide the name and contact information of the person that can answer questions regarding your traceability plan and records.

- Be kept for a minimum of 2 years.

- Be updated as needed to reflect your current practices. When you create an updated plan, you must save your previous Food Traceability Plan for at least 2 years.

See an example of a Food Traceability Plan. -

What needs to be on my Food Traceability Plan if my restaurant ships food to other restaurants or suppliers?

The Traceability Plan must:- Explain the process used to maintain the required food tracking records.

- Describe how you identify foods on the Food Traceability List that are on your menu at any time.

- Show how you assign traceability lot codes (TLC) to foods on the Food Traceability List (FTL).

- Provide the name and contact information of the person that can answer questions regarding your traceability plan and records.

- Be kept for a minimum of 2 years.

- Be updated as needed to reflect your current practices. When you create an updated plan, you must save your previous Food Traceability Plan for at least 2 years.

-

What needs to be on my food traceability plan if my restaurant grows or raises a food on the Food Traceability List (other than eggs)?

Your plan must include a map showing the location areas where you grow or raise these foods.- The map must show the location and name of each field (or other growing area) where you grow food on the Food Traceability List, including geographic coordinates and any other information needed to identify the location of each field or growing area.

- For aquaculture, the map must show the location and name of each container (e.g., pond, pool, tank, cage) in which you raise seafood on the Food Traceability List, including geographic coordinates and any other information needed to identify the location of each container.

In addition, your plan must meet these other Food Traceability Plan requirements:- Explain the process used to maintain the required food tracking records.

- Describe how you identify foods on the Food Traceability List that are on your menu at any time.

- Show how you assign traceability lot codes (TLC) to foods on the Food Traceability List (FTL).

- Provide the name and contact information of the person that can answer questions regarding your traceability plan and records.

- Be kept for a minimum of 2 years.

- Be updated as needed to reflect your current practices. When you create an updated plan, you must save your previous Food Traceability Plan for at least 2 years.

-

How long must I keep the records required by the rule?

In most cases, records containing the Key Data Elements information must be kept for two years from the date you created or obtained the records. One exception is for records maintained by a restaurant for food bought directly from a farm. Those records must be maintained for 180 days. -

How does the rule affect restaurants? What Key Data Elements (KDEs) are required to be kept by restaurants? Do restaurants have to link the KDEs and traceability lot codes to their recipes/meals?

Restaurants do not need to attach KDEs and TLCs to specific recipes and meals. However, restaurants do need to keep records on any FTL food that they receive from a supplier or for any food they grow or ship to another business. -

What key data elements (KDEs) must be recorded, maintained, and linked to a FTL food’s Traceability Lot Code (TLC)?

These are the Key Data Elements must be linked, recorded, and maintained for a FTL food:- Traceability Lot Code

- Food quantity and unit measurement

- Food description

- Previous supplier and location

- Restaurant Receiving Location (ex., Load dock, receiving area of the restaurant)

- Date you received the food

- The name of and the location description for the initial supplier that assigned the traceability lot code. Examples of traceability lot code sources include, but are not limited to:

- The FDA Food Facility Registration Number for the traceability lot code source

- A web address that provides FDA with the location description/address for the traceability lot code source.

- Reference document and reference document number.

Please see Sample KDE record below:

FTL Food Description Date Received Restaurant Receiving

AreaReference

Document & ID

NUMBERQTY/UNITS Traceability Lot

CodePrevious Supplier &

LocationTLC Supplier & Location Shell Eggs Large, Grade A 12/1/2023 Back Door

Receiving AreaReceipt:#23595 500/24 packs BR2546442 Sodexo @ 2301 Maitland

Center PkwySte 350,

Maitland, FL 32751Humpty Dumpty Eggs @

256 Gingerbread Lane,

Tallahassee, FL 23200 -

Since distributors and suppliers deliver foods to restaurants and have internal traceability systems, can they maintain and store key data elements (KDEs) for my restaurant?

Yes, the FDA encourages restaurants to work with their suppliers to decide the best way to store and access required KDE information.

Restaurants are required to keep receiving records. Most of these records will be sent to the restaurant by the business shipping the food. Restaurants may have another business create and maintain the required KDE records on your restaurant’s behalf. Your restaurant will still be responsible for ensuring the KDE records can be provided onsite to the FDA within 24 hours of their official review request. -

How will I receive my suppliers required key data element (KDE) records?

it is important you talk with your suppliers as soon as possible to understand how they intend to share the required KDE information with your restaurant as it is your responsibility to make sure you maintain all the KDEs required under the rule.

The FDA does not require a specific format or technology for maintaining and sharing records with restaurants. You may receive records from your suppliers via any of the methods currently used by the food industry or any new methods created to comply with the FDAs Traceability Rule. This may include bills of lading, invoices, Advanced Ship Notices (ASNs), Electronic Data Interchanges (EDIs), packing lists, case labels, 2-D barcodes, etc. -

Does FDA require a specific technology to store records? Are there any exemptions to having to keep tracking information in an electronic, sortable spreadsheet?

No. The FDAs Food Traceability Rule does not require any specific technology to be used to keep the required records.

Restaurants with an average annual food sale of over $250,000 but less than 1 million are exempt from the requirement to provide FDA with an electronic, sortable spreadsheet upon request. However, these restaurants must still maintain the records required by the rule. These records must be kept as original paper or electronic or true copies (such as photocopies, pictures, scanned copies, or other accurate reproductions of the original records). Records must be legible and stored to prevent deterioration or loss. Electronic records may include working electronic links to the information required to be maintained under the final rule. -

What are the requirements if I am required to do my record keeping in an electronic, sortable spreadsheet?

If your average annual food sales are over 1 Million you must keep the FTL Food records in an electronic, sortable spreadsheet. Spreadsheet requirements include:- Recording and tracking all required key data element (KDE) information for foods on the Food Traceability List*. Electronic records may include links to the information required to be maintained under the rule.

- Keeping all required data for a minimum of two years.

- Providing FDA access to the spreadsheet within 24 hours of their request.

This is an example of what the spreadsheet might look like:

FTL Food Description Date Received Restaurant Receiving

AreaReference

Document & ID

NUMBERQTY/UNITS Traceability Lot

CodePrevious Supplier &

LocationTLC Supplier & Location Shell Eggs Large, Grade A 12/1/2023 Back Door

Receiving AreaReceipt:#23595 500/24 packs BR2546442 Sodexo @ 2301 Maitland

Center PkwySte 350,

Maitland, FL 32751Humpty Dumpty Eggs @

256 Gingerbread Lane,

Tallahassee, FL 23200

Additional record-keeping requirements:- You may have other organization(s) create and maintain records on your behalf, but you are still responsible for ensuring that those records can be accessed and provided onsite within 24 hours of FDA request.

- Offsite records storage is permitted if the records can be accessed and provided onsite within 24 hours of FDA request. Electronic records are onsite if they are accessible from an onsite location.

- Records must be maintained as original paper or electronic records or true copies.

- Records must be legible and stored to prevent deterioration or loss.

-

What Key Data Elements (KDEs) does my restaurant need to keep records for if my restaurant receives food from a business that is not subject to the Food Traceability Rule?

If a restaurant receives food from a person or business that does not need to follow the rule, you must create, maintain, and link to the traceability lot code of the food, the following KDEs:

- Traceability Lot Code

- Food quantity and unit measurement

- FTL Food and description

- Previous supplier and location

- Restaurant Receiving Location

- Date you received the food

- Reference document and reference document ID number

Please see Sample KDE record below:

FTL Food Description Date Received Restaurant Receiving

AreaReference

Document & ID

NUMBERQTY/UNITS Traceability Lot

CodePrevious Supplier &

LocationTLC Supplier & Location Shell Eggs Large, Grade A 12/1/2023 Back Door

Receiving AreaReceipt:#23595 500/24 packs BR2546442 Sodexo @ 2301 Maitland

Center PkwySte 350,

Maitland, FL 32751Humpty Dumpty Eggs @

256 Gingerbread Lane,

Tallahassee, FL 23200

In most situations, the food shipper will send you most of the above KDEs. You may be required to keep other records if you perform other CTEs. Your supplier may be able to keep and store KDE information for you, however you are still responsible for providing access to that information within 24 hours of FDA official request.